Lonza has expanded its presence in China by signing a deal under which GE Healthcare will deliver a KUBio off-the-shelf biologics facility to Lonza in Guangzhou. The new facility is expected to give Lonza Pharma & Biotech a strategic base in China for providing CDMO services in the country.

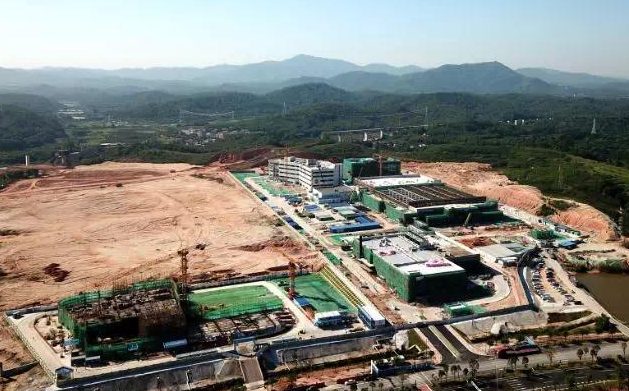

By working with GE Healthcare to develop the new facility, Lonza expects to offer its suite of antibody development services and manufacture GMP-certified batches by 2020. The two companies will work closely on the design of the 17,000-square-meter site, which will include 6500 square-meters of lab space and one KUBio facility, according to Karen Fallen, head of clinical development and manufacturing, Lonza Pharma & Biotech.

“We looked at several options for sites in China, ranging from our own build to working with partners. The project in Guangzhou was a combination of a dynamic regional development authority (GDD) and the possibility of taking over the facility in the biopark that GE is co-developing with GDD,” Fallen tells GEN. “This combination gives us access to a growing biohub with the advantage of rapid build and start of operations.”

Lonza will combine GE’s KUBio concept of single-use bioreactors for GMP manufacturing with its own platforms and expertise in development, including cell line construction, cell banking, and process development, notes Fallen, who adds that this setup also gives Lonza the option to scale when needed.

The labs will house Lonza’s proprietary platforms for cell-line construction, including the GS Xceed® Gene Expression System, as well as process development, cell banking, and pilot labs. The KUBio unit will enable small-scale GMP manufacturing equipped with GE Healthcare’s single-use biomanufacturing technologies, including 1000- and 2000-L bioreactors, combined with Lonza’s automation platforms for clinical and early commercial supply.

Lonza has been present in China since 1995. “We now have operations across the group in Guangdong (the new biologics facility is also located in this province) and Jiangsu provinces as well as Shanghai,” continues Fallen. “In Lonza’s Pharma & Biotech segment, we have a small molecule API plant in the Nansha district of Guangzhou, which has been operational since 2003. This is our second small molecule API site outside of Visp, Switzerland.”

“This partnership is the ideal way for Lonza to bring our expertise and technology to China,” adds Marc Funk, COO, Lonza Pharma & Biotech. “The combination of a strong and experienced technology provider with a long history in China, together with a dynamic regional authority, means that we can rapidly offer services to customers and ultimately get innovative therapies to patients more quickly.”

The new facility in Guangzhou is Lonza’s first biomanufacturing center in China and reflects the increasing need for manufacturing antibody therapies specifically for innovator companies looking to take new therapies to market, Fallen points out.

“The facility, which will offer development and manufacturing from preclinical to early commercial, will serve Chinese companies developing innovative medicines for the domestic market as well as those with a strategy of expanding to global markets,” says Fallen. “In addition, we will work with multinational companies with manufacturing requirements in China.”

Fallen says that GDD is keen to develop biomanufacturing in the region and will be supporting Lonza, including providing assistance for recruitment and training of staff from the local region. “In addition, GE and GDD are working together to make a new biomanufacturing training program available based on a successful European model,” she continues.

“With Lonza coming onsite, a hub of biotech is truly taking shape,” says Emmanuel Ligner, president and CEO, GE Healthcare Life Sciences. “This agreement is yet another step in realizing our vision of enabling and supporting manufacturers of all sizes to quickly deploy capacity and meet increasing customer demand for biologics.”

Lonza’s GS Xceed Gene Expression System is a CHO host cell line in which both alleles of the endogenous glutamine synthetase gene have been knocked out, leading to a requirement for exogenous glutamine. The target gene is introduced in a vector that also contains a replacement gene for glutamine synthetase, which allows for easy screening of transfected clones.

“A range of different vectors are available which means the system is extremely flexible and can be used for standard format mAbs and harder to express proteins such as single chain Fv fragments, fusion proteins, Fc fragments, FAbs, and complex gylcoproteins,” says Fallen. “Recent additions to the toolbox also means that expression of three to four different genes is possible, for bsAbs and other multichain proteins.”