Decades worth of work from tree geneticists are now colliding with AI and multiplex CRISPR to overcome a major barrier to the sustainable production of wood fibers while improving wood properties. Their results offer the promise of making fiber manufacturing for a wide range of products—from cardboard and paper to diapers and clothing—greener, cheaper, and more efficient.

“The [CRISPR-edited wood] that we’ve made can have a tremendous impact on industrial operations and building the bioeconomy,” co-senior author Rodolphe Barrangou, PhD, professor in the Department of Food, Bioprocessing, and Nutrition Sciences at North Carolina State University (NCSU), told GEN. “The financial, operational, and environmental benefits are real, and we hope that is going to provide a sense of urgency and impetus for a lot of our colleagues, governmental agencies, investors, innovators, and entrepreneurs.”

Barrangou and colleagues reported on their development in a paper titled “Multiplex CRISPR editing of wood for sustainable fiber production,” in Science.

Turning over a new leaf

Co-senior author Jack P. Wang, professor at the College of Natural Resources at NCSU and Co-founder of TreeCo, said that the importance of trees for the environment and as our major source of natural materials and resources and the largest biological carbon sink on earth means that they must be used responsibly. They are pillars of ecosystems and the bioeconomy. In North Carolina, forestry contributes over $35 billion to the local economy and supports approximately 140,000 jobs.

That’s why Wang thinks it’s perplexing why the genetic materials for trees used globally for sustainable fiber materials are mostly from domesticated trees.

“If you think about how far along agriculture, in general, has moved and how far along therapeutics has moved, there are substantial opportunities in forestry to make tangible benefits that could make our natural resources much more efficient, productive, sustainable, and of higher quality,” said Wang.

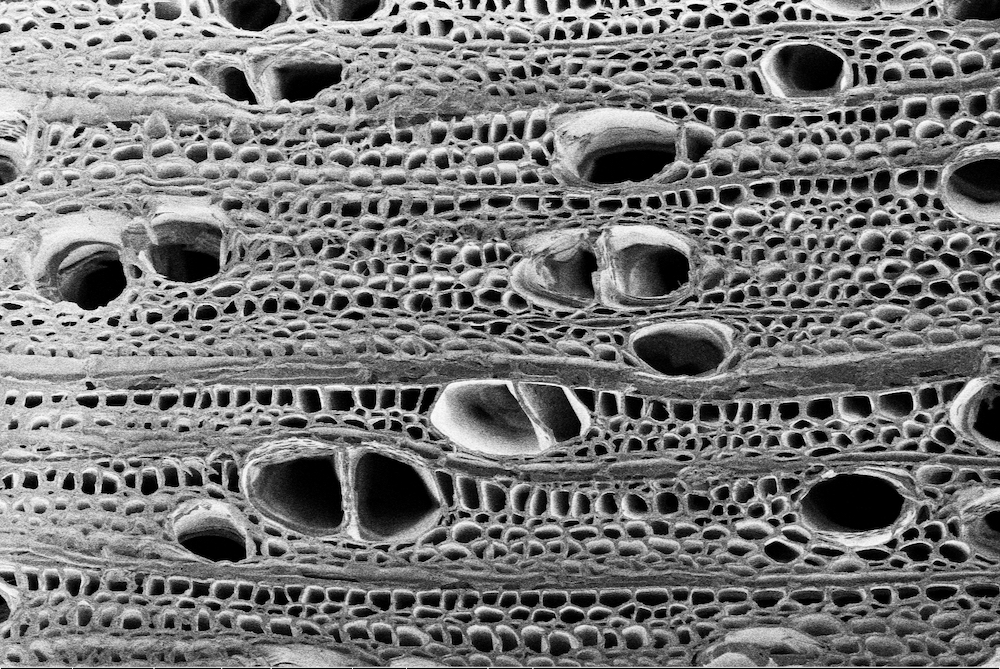

The ability to efficiently isolate the desired cellulosic fibers from wood is largely determined by the content and composition of lignin in the wood. The domestication of forest trees for a more sustainable fiber bioeconomy has long been hindered by the complexity and plasticity of lignin, a biopolymer in wood that is recalcitrant to chemical and enzymatic degradation.

Over the last 50 years, researchers have investigated the individual components of lignin biosynthesis to help understand how changes may affect lignin content and composition in diverse plant species. However, much work has predominantly focused on the modification of single genes or gene families, whereas the combinatorial effects of multigenic perturbations have remained elusive.

Against the grain

Decades of research in Wang’s lab and his predecessors Ronald R. Sederoff, PhD, and Vincent L. Chiang, PhD, who are authors of the Science research article, generated large amounts of genetics and omics data that were processed with AI to predict and then sort through more than 69,000 different multigenic gene-editing strategies targeting 21 important genes associated with lignin production.

“[Trees] are very complex organisms that can thrive for hundreds of years, so their genetics are hard to understand,” said Wang. “That’s why we needed that machine learning model to really decipher and understand the genetic regulation for information and then modify them using CRISPR in ways that can produce woody materials that are compatible with industrial processes or the conversion to useful products.”

The research team used predictive modeling to set goals of lowering lignin levels, increasing the carbohydrate to lignin (C/L) ratio, and increasing the ratio of two important lignin building blocks—syringyl to guaiacyl (S/G)—in poplar trees. These combined chemical characteristics represent a fiber production sweet spot, the researchers suggest. The efficiencies found in fiber production could also reduce greenhouse gases associated with pulp production by up to 20% if reduced lignin and increased C/L and S/G ratios are achieved in trees at an industrial scale.

From these, they deduced seven different genome editing strategies targeting the concurrent alteration of up to six genes. From there, the researchers selected the seven best strategies that modeling suggested would lead to trees that would attain the desired characteristics. These included 35% less lignin than wild, or unmodified, trees, C/L ratios that were more than 200% higher than wild trees, S/G ratios that were also more than 200% higher than wild trees, and tree growth rates that were similar to wild trees. The C/L ratio is an indicator of the potential maximum cellulosic yield for wood fiber. The seven strategies encompassed various numbers of target genes (from three to six) and were selected on the basis of the extent and robustness of predicted improvement in fiber traits (reduced lignin, increased S/GandC/L ratios, and good growth).

With multiplex CRISPR technology, they produced 174 edited poplar variants, which they planted, grew for months to several feet tall, and harvested for analysis and the generation of paper with gains that translate to industrial processing. The edited lines exhibited varying extents of loss-of-function mutations of the target genes. After six months in an NC State greenhouse, an examination of those trees showed reduced lignin content of up to 50% in some varieties, as well as a 228% increase in the C/L ratio in others.

The study also included sophisticated pulp production mill models that suggest reduced lignin content in trees could increase pulp yield and reduce so-called black liquor, the major byproduct of pulping, which could help mills produce up to 40% more sustainable fibers. Low-lignin wood could reduce the solid content of black liquor, thereby debottlenecking the recovery boiler, arguably the most crucial and rate-limiting energetic component of pulp mills.

“What was remarkable is that through this process of producing the paper, we plugged the numbers in into a technical economic model based on an actual pulp mill operation out of South America and discovered that the use of CRISPR-edited wood would potentially debottleneck one of the most critical industrial processes in fiber production,” said Wang. “By doing so, it enabled a pulp mill to potentially increase the production capacity substantially, upwards of 20–40% of the production of this very important sustainable biomaterial.”

Tremendous financial benefits may be obtained by reducing lignin from 28% to 16% and by increasing the S/G ratio from 2.8 to 4.0. Increasing the C/L ratio in wood also means that less biomass is required to produce the same amount of cellulose, while the efficiencies found in fiber production could in addition reduce greenhouse gases associated with pulp production by up to 20% if reduced lignin and increased C/L and S/G ratios are achieved in trees at industrial scale.

“When producing fiber materials from wood through the process of pulping, roughly 50% of the tree or wood is burned into carbon dioxide, resulting in a substantial amount of carbon dioxide being released into the atmosphere,” said Wang. “By using CRISPR-Wood, the model indicates that the amount of carbon dioxide released into the environment can be reduced by upwards of 20%, resulting in a substantial reduction in the global warming potential,” said Wang. “By extension, the carbon that does not go into the atmosphere is now sequestered as useful fiber materials to sustain the increasing demand for packaging cardboard, toilet paper, and diapers—even sustainable clothing nowadays made from wood.

Next steps may include continued greenhouse tests to see how the gene-edited trees perform compared to wild trees. Later, the team hopes to use field trials to gauge whether the gene-edited trees can handle the stresses provided by life outdoors, outside the controlled greenhouse environment. Moving forward, it will be necessary to monitor the impact of the genome editing outcomes on the tree’s phenotypic properties and traits relevant to the industry in long-term field trials.

Trees as a cure

Barrangou—who is also co-founder, president, and chief scientific officer of TreeCo as well as a co-founder and member of the scientific advisory board of Intellia Therapeutics—believes that a tree’s effect on global health may exceed that of medicine at extraordinary cost and speed.

“CRISPR has shown success in the clinic, with gene therapy trials underway and people having been ‘cured,’ but it took eight years to dose the first patient, collectively, and two more years to dose a couple of dozen patients,” said Barrangou. “While we’ve dosed hundreds of patients, how long is it going to take to reach a million people? It’s going to take a long time. But the number of people that can benefit from editing trees is in excess of 10 billion—everybody who lives here today plus people who are going to be born over the lifespan of those trees.”

Besides the legitimate and tangible industrial gains, this research also shows global warming gains at a time when sustainability controls are not being met.

“The carbon solutions are neither hopeful nor convincing,” said Barrangou. “When you think about the fact that about 57% of all carbon on the planet is in trees, editing trees is arguably the best path to address that and achieve what we intend to achieve as a planet in light of global warming. The cost-benefit ratio of gene editing trees is far cheaper than that of gene editing therapies, which right now can cost around a million dollars for an individual patient and are not a realistic solution to be applied to the entire world population.”

This combination of machine learning technologies with CRISPR and genetic insights can produce very unique trees that have tangible environmental and economic benefits. Importantly, this approach is applicable and translational to other species of wood, and Barrangou said that they’re already working on other species of more substantial industrial and operational interest, such as eucalyptus and pine.

“It’s the start of a new era in sustainable forestry,” said Barrangou. “A lot of regular agencies in the U.S. and throughout the world are now familiar with the CRISPR technologies and are more comfortable with the deployment of different CRISPR applications in different fields for different purposes.”

And just like with everything else in life, timing is everything. “If we had done this 10 years ago, the world would not be ready for it, and 10 years later, it’s too late to save the world,” said Barrangou. “Now, it’s not too early, and hopefully it’s not too late.”