It’s a well-known fact that animal models are imperfect models. Hence the development of alternative models. These include organoid systems, which incorporate human cells and tissues. However, these systems are imperfect, too. For example, they rely on tissues that are harvested from people—tissues that are limited in quantity. Also, these systems may lack some of the cell types and the vascular features found in biopsied tissue.

The limitations of organoid systems complicate preclinical research and the development of new therapeutics. Indeed, therapeutics may behave differently in organoid systems than they do in the human body. Such discrepancies are especially problematic if individualized insights are needed, for example, in efforts to personalize the care of cancer patients.

“We found organoid technology wasn’t very reproducible in terms of high throughput and consistency,” says Ishani Malhotra, founder and CEO of Carcinotech. That limitation relegates organoid technologies to “very in-depth studies” or “tumor assays that are specific to one or two compounds.”

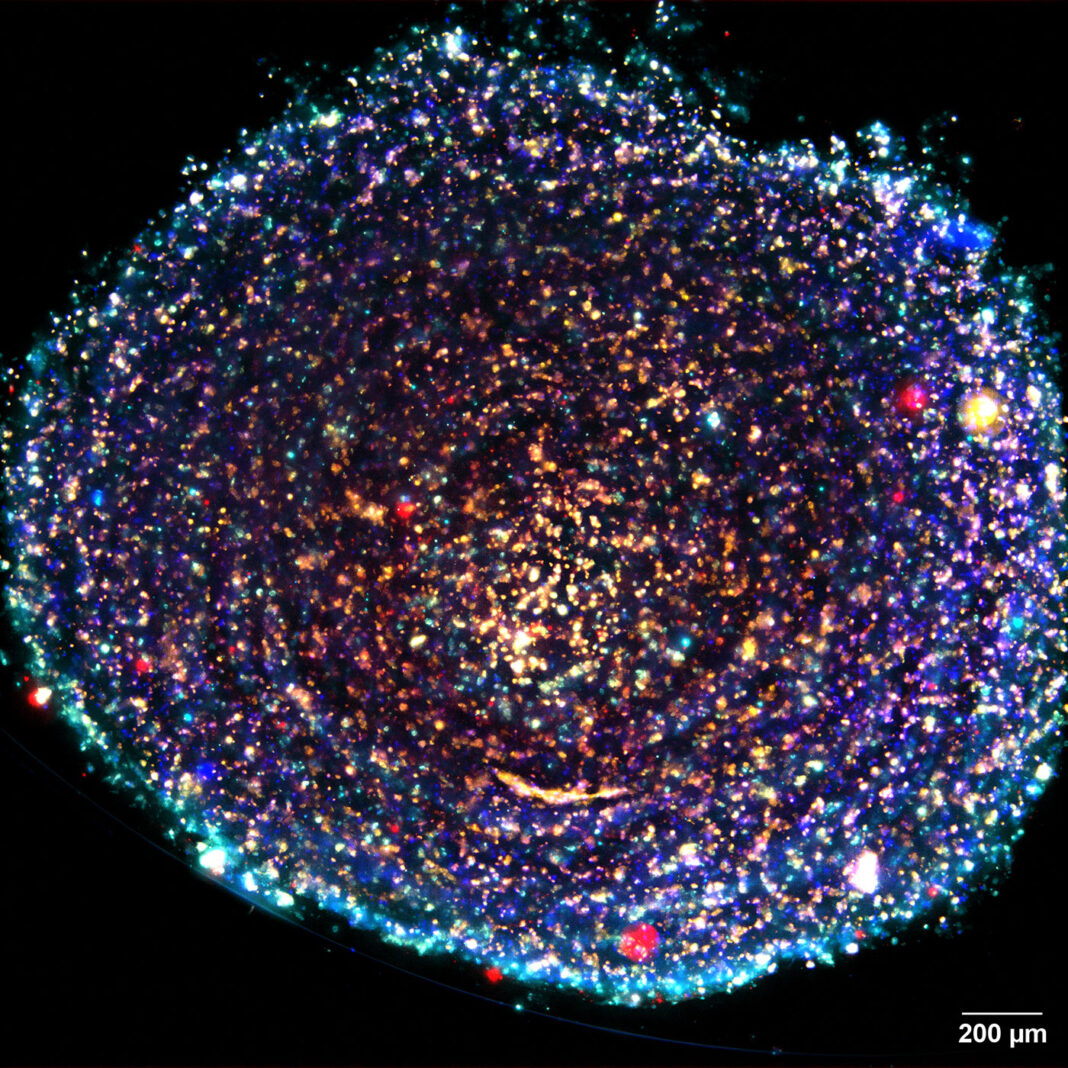

Carcinotech is addressing that challenge by 3D printing tumors that more closely mimic human biopsies. It does this by including a robust complement of cells and, soon, the tumor vasculature. This results in more physiologically relevant, human-based tumor tissues and also provides high quantities of 3D-printed tumors from individual tumor biopsies. Therefore, scientists can perform more assays faster, winnowing out ineffective candidates early.

A wide portfolio

Carcinotech offers 3D-printed tumors for lung, brain, breast, colorectal, and ovarian cancers, as well as custom options. The company has plans to vascularize some of its printed tumors and to begin developing 3D-printed tumors for pediatric cancers.

“There aren’t many—if any—3D models that properly replicate solid tumors when there is a cancer diagnosis in children,” Malhotra remarks. “It’s very hard to find samples. This is a rare area that we’re very excited to get into.” If better 3D models were more readily available, pediatric oncologists could use them to determine the best treatment options more quickly.

Malhotra asserts that 3D-printed vascularized tumors represent an “advanced offering” that will replicate the blood vessels from a biopsy as well as the tumor microenvironment. She believes that these models will more closely resemble the patient’s tissue in terms of perfusion and reactions to therapeutics.

“Vascularized 3D-printed tumors would be offered mainly for efficacy studies in preclinical trials,” Malhotra says. These models, she adds, would allow scientists to rely less on mouse-based studies at this stage of testing. The use of printed tumors, organ-on-a-chip devices, and other such models may get a boost from the FDA Modernization Act 2.0, which was signed into law at the end of 2022. It “authorizes the use of certain alternatives” to animal models in drug testing.

Carcinotech also plans to develop irradiated 3D-printed tumor models. According to Malhotra, such models could be used to reveal how irradiated tumors respond to various therapeutics.

Key goals

With a background in cancer diagnostics and bioengineering—and a master’s degree in regenerative medicine from the University of Edinburgh—Malhotra is familiar with the improvements that cancer surgeons and oncologists hope to see in preclinical testing. She relates that they want humanized tissues and expanded biopsy samples that would allow more assays to be performed on the same tumor model. They also want to identify ineffective therapeutic candidates sooner in the development process.

To realize these hopes, Malhotra founded Carcinotech about five years ago. While building the company, she has worked closely with organizations such as the University of Edinburgh, Cancer Research UK, Cellink, Edinburgh Innovations, and Scottish Enterprise.

3D-printed tumors vs. organoids

“Our 3D-printed tumors are much more complex than organoids,” Malhotra declares. “They have so many different cell types—about 16 or 17—in one printed tumor, and a whole immune panel can be profiled within these printed tumors.”

The 3D-printed tumors also offer consistency, which is important because consistent printed tumors mean consistent results across multiple assays. Indeed, consistency is maintained even though the number of printed samples derived from a single patient sample could exceed 400.

This level of consistency puts 3D-printed tumors “one step above the organoids,” Malhotra argues. Although organoids are becoming more common as tools within lead optimization and target validation, only a few organoids are available per biopsy.

Lower costs, shorter timelines

Carcinotech anticipates that its main customers will be pharmaceutical companies, contract research organizations, and cell and gene therapy companies. Carcinotech’s 3D-printed tumors “also could be used for stratified diagnoses or for segmenting patients for clinical trials,” Malhotra notes. “We can perform the testing in-house, or we can provide plates of 3D-printed tumors so clients can do their own testing.”

One of the benefits of 3D-printed tumors is capital conservation. “During the early stages of drug discovery, a company can spend $7 to $8 million on preclinical testing per compound,” she remarks. “Often, we can reduce that by more than half because our models provide much more data.”

“Scientists could use 50 to 200 mice for efficacy studies, or they could replace them with 100 patient profiles using 3D-printed tumors. The latter option would let the scientists perform the studies within two years rather than the seven years those studies normally take.”

Gradual recognition

“It was difficult for potential clients to understand the difference between our technology and organoids,” Malhotra recalls. “They began comparing based on price, and organoids are definitely less expensive.”

That’s less of a hurdle today, and companies such as Cellink—which announced an agreement with Carcinotech last October—see the value in 3D-printed tumors and are partnering to produce physiologically relevant, quality-controlled, and highly accurate tumor models.

That leaves company growth and expansion as the immediate goal. “Our challenge,” Malhotra points out, “is making sure these 3D-printed tumors can be used by drug manufacturers all over the world.” To that end, Carcinotech is growing its team and laying plans to expand beyond the United Kingdom and Europe. The company aims to enter the U.S. market “in the near future.”

In January, Carcinotech raised $5.3 million in new funding (led by Eos Advisory and Investment Fund for Scotland). That influx will help Carcinotech strengthen partnerships in North America. At present, Malhotra is looking at options for a sales office and production facilities in the United States.