March 1, 2013 (Vol. 33, No. 5)

Ultrastable Silica Sorbents Work to Handle Aggressive Wash Conditions

HPLC is a widely used tool in peptide and protein purification. One of the challenges in this process is maximizing the lifetime of the bulk media sorbents or prepacked columns, which degrade due to the buildup of material in the column.

There are many causes of performance degradation and backpressure buildup, including incomplete removal of precipitated compounds, strongly retained sample components and dissolution or other degradation of the sorbent.

By nature, peptides and proteins tend to aggregate, making it difficult or impossible to regenerate media under standard wash conditions. Proteins such as insulin are prepared by recombinant techniques and contain nonsoluble materials that need to be washed and eliminated periodically from the purification media to maintain column performance.

Peptides and proteins produced by chemical synthesis contain multiple disulfide bridges. During folding of these compounds, polymerization and scrambling may occur, which can lead to the formation of impurities. These impurities can aggregate during purification under reversed-phase conditions and clog the column inlet frit or bind to the media itself.

Washing techniques are commonly used to regenerate media, typically by treating it with strong basic solutions that remove performance-damaging impurities from the column frit and/or packed media bed.

Columns are typically replaced when washing procedures are no longer able to restore column performance or when backpressure remains high. Most reversed phase silica-based sorbents can only withstand standard wash conditions of acetic acid, methanol and low concentrations of sodium hydroxide. The use of more aggressive wash conditions offers significant improvements in cleaning effectiveness but can only be carried out with media of wide pH stability.

Polymeric sorbents are able to withstand washing with higher concentrations of sodium hydroxide but they do not provide the needed selectivity or efficiency to make them competitive with silica-based media for protein and peptide purification.

Higher Selectivity and Efficiency

Newer silica sorbents such as Gemini from Phenomenex offer increased selectivity, efficiency, and extended pH stability. During the final stage of Gemini manufacturing, a unique silica-organic layer is grafted to create a completely new composite particle.

Because the internal base silica is not altered by this manufacturing process, the particle retains its mechanical strength and rigidity along with excellent efficiency for increased resolution, while the silica-organic shell protects the particle from chemical attack.

The Gemini material thus allows the use of more aggressive and effective wash conditions without compromising the integrity of the media. Gemini C18, C6-Phenyl, and NX-C18 media are all compatible with very aggressive wash conditions and remain chemically stable even with high concentrations of sodium hydroxide.

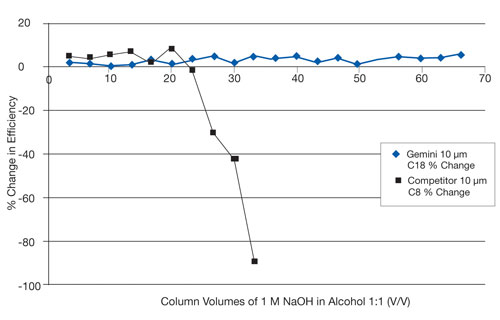

Figure 1. Change in peak efficiency on Gemini C18 and a typical reversed phase silica-based sorbent during chemical stability testing with sodium hydroxide in alcohol.

Experiments Carried Out

To test this novel material, a series of media performance experiments under caustic wash was carried out. Figure 1 shows results of repeated wash cycles with a sodium hydroxide solution for Gemini C18 and a typical reversed-phase silica-based sorbent.

For stability testing experiments the hydrophobic probe was naphthalene, the flow rate was set at 1 mL/min, temperature was ambient, and UV detection was 254 nm. The mobile phase was a solution of 20 mM acetic acid in alcohol 1:1 (V/V). The caustic washes were performed under the same conditions of flow rate and temperature using 3.3 column volumes of 1 M NaOH in alcohol 1:1 (V/V).

After the caustic washes were performed, the column was neutralized by passing 4 column volumes of 20 mM acetic acid in alcohol 1:1 (V/V). The column efficiency as determined by the test probe was monitored after each washing cycle. The Gemini C18 media maintained a stable performance at more than twice the caustic wash exposure compared to the reversed phase silica-based sorbent, which started to dissolve, creating voids in the column that resulted in significantly lower performance.

Figure 2 shows fraction purity. For the protein purification experiments the protein was dissolved at 10 mg/mL, the injection volume was 5 mL, the flow rate was set at 1 mL/min, temperature was ambient, and UV detection was set at 260 nm.

The protein was purified using a 15–25% alcohol in water gradient over 25 minutes. After three preparative protein purifications, the columns were washed and neutralized according to the procedure described previously for the Figure 1 experiments. The Gemini C18 media maintained constant fraction purity at more than twice the caustic wash exposure compared to the reversed phase silica-based sorbent.

Purifications on the silica-based column were stopped due to excessive system backpressure during the washing steps. Once again, the high pH wash conditions caused the dissolution of the silica-based sorbent, resulting in the formation of media fines, which lowered purification performance and increased backpressure.

Figure 2. Purity of recovered protein with repeated purification and wash cycles using Gemini C18 and a typical reversed phase silica-based column.

Figure 3 shows the backpressure comparison of the two columns. Gemini C18 provides consistent chromatographic performance without backpressure increases under aggressive wash conditions. Purifications on the typical silica-based column were stopped due to excessive system backpressure during the washing steps.

After 20 column volumes of caustic wash, the silica-based column exceeded system pressure limits while the Gemini C18 backpressure remained stable even after more than 50 column volumes of aggressive caustic wash.

All analyses and purifications were performed on an Agilent 1100 HPLC system from equipped with quaternary pump, degasser, variable wavelength UV detector, and autosampler.

Gemini sorbents are compatible with aggressive caustic wash conditions typically reserved for polymeric sorbents. The chemical stability of the Gemini product line delivers more purification runs between column replacements, for time and cost savings in the preparative purification of peptides and proteins.

Figure 3. Maximum column backpressure during sodium hydroxide washes between protein purification cycles. Purifications on the silica-based column were stopped due to excessive backpressure during the wash step.

Marc Jacob, Ph.D. ([email protected]), is product manager for chiral and preparative chromatography at Phenomenex. Carl Sanchez, Ph.D., is senior research scientist, Ismail Rustamov, Ph.D., is R&D group leader, media and technology development, and JT Presley III is brand manager at the company.