May 1, 2011 (Vol. 31, No. 9)

Innovative Formats and Applications Extend Range Beyond Conventional Analyses

Protein microarrays are many things to many people. Like the more mature DNA “chips”, they are often patterns of tiny spots arrayed on a microscope-type slide, used to determine the makeup and amount of protein in a sample in a multiplex fashion. But not always.

Just as there are a wide variety of uniplex protein assays, there are a variety of multiplex protein assays as well. Chips, yes—but they’re also found arrayed on the bottom of microwell plates and as beads in a tube. These, and others, were hot topics at BIT Life Sciences’ recent “PepCon” protein and peptide conference.

Protein chips are typically laid out by using a contact pin spotter or a noncontact microarrayer to immobilize ligands on a substrate. These can be antibodies, aptamers, peptides, or other molecules whose binding affinity is used to query samples. In the case of peptides, arrays can be created from random libraries for biomarker discovery, for example, or from series of overlapping protein sequences for epitope mapping.

For PEPperPRINT’s PEPperCHIP® microarrays, peptides are synthesized directly on a functionalized glass slide with a 20-color laser printer. The activated amino acids, which are embedded in the toner, are released from the solid matrix material upon melting. “The toner matrix liquefies and the activated amino acids can approach amino groups on the surface of the chip,” explained CEO Volker Stadler, Ph.D., “and that way they can couple covalently to form the peptides on the chip.” Up to 20 mers are produced by sequential rounds of heating, washing, and deprotection.

Toner is heated to just above the melting temperature of the amino acids so there is little or no evaporation. “And because the toner matrix has an oily consistency, it doesn’t spread on the slide surface. This is a key feature that allows us to achieve much higher spot densities compared to other technologies.”

Another major advantage of this approach, Dr. Stadler added, is that the combinatorial laser-printing process allows for one-off microarrays to be easily produced. “It’s the same effort to synthesize hundreds of different or hundreds of the same peptide microarrays.” Thus the Heidelberg-based biotech can offer custom microscope slide-sized arrays with about 9,000 peptides on a slide for around c900, or about c0.10 per feature. These high-density arrays allow for low per-feature reagent consumption as well, typically requiring only about 5–10 microliters of sample per chip.

Standard PEPperCHIPs can be processed and read with standard lab equipment. PEPperPRINT also offers larger slide formats with up to 275,000 features.

The company, which has been developing its technology for the past decade, began offering screening services in early 2010. In March of this year it started marketing chips for its customers to use in-house. It is currently focused on serology and antibody analysis—“it’s the most straightforward way to work with peptide chips,” Dr. Stadler said.

The chips can also be used for kinase, acetylase, deacetylase, and other enzymatic analyses, “but we don’t have enough experience in the field to really know that they work as well as for standard applications,” Dr. Stadler confessed. “So we have collaborators testing the chips now” to see how they perform and to elicit feedback on how to improve them for enzymatic assays.

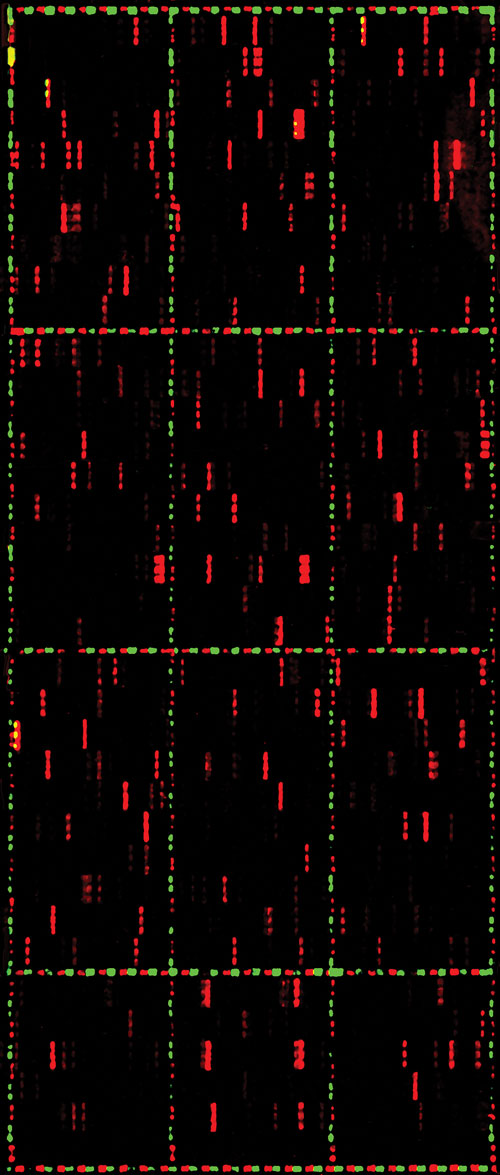

Fingerprint analysis of serum antibodies with PEPperPRINT’s new peptide microarray platform.

Don’t Cry

Robert Sack, Ph.D., SUNY College of Optometry professor, uses conventional commercial microarrays in slightly unconventional ways, and in the process has come to some disturbing conclusions about standard protocols.

Specifically, he uses planar arrays and microwell plate arrays, along with techniques such as HPLC and immunoprecipitation, to identify and characterize the chemokines and cytokines in lacrimal fluid.

“There is a tremendous difference in the host defense mechanism between the open and closed eye,” Dr. Sack says. While the eye is closed, there is a fluid layer with no place to go. Bacteria stimulate epithelial cells, which in turn recruit immune cells to digest the microorganisms, the result being high levels of peroxidases, proteases, interferons, interleukins, and TNF alpha. “You have a tissue, the cornea, which is lying right next to it and is extremely vulnerable to any change. Any neovascularization, any scarring, can have a devastating effect. Yet the eyes of a person in a coma can stay closed for years without any major effect.”

Earlier work had shown that protease inhibitors were released from the ocular surface, and Dr. Sack wanted to know how the cytokines were kept in check. In his research, he found that “virtually all the inflammatory cytokines and immune modulating cytokines were in the form of macromolecular inactive complexes.”

Many of these were not detectable using standard microarray protocols, or they gave wildly varying results. Yet under the right conditions, Dr. Sack was able to show that the cytokines were complexed with soluble receptors and another protein that tags it for destruction.

Tears contain various surfactants and other substances with a high affinity for plastic, and thus show a high nonspecific reactivity in many assays. Using the correct blocking agents and “running proper controls, such as spiking samples with different types of tears from different individuals (because the levels of these interfering factors vary enormously from one sample to another),” are only part of the solution.

Because the cytokines are found in complexes, they may not be detectable using the antibodies supplied by the assay manufacturer. “The way I was able to show these complexes was to take standard arrays and substitute antibodies for the complexing proteins in place of the normal secondary antibody,” Dr. Sack explained. Complexes were isolated by molecular sieve HPLC and characterized.

From Membrane to Microarray

Although membrane-bound receptors comprise a major portion of the pharmaceutical industry’s target portfolio, they pose a challenge for microarrays. They are notoriously difficult to isolate, and the purified proteins are very likely to lose their function when they’re immobilized. GPCRs, for example, “have seven transmembrane domains that have to remain intact,” pointed out Fang Lai, Ph.D., research manager for Corning. “They have to remain associated with lipids to maintain their structure.”

The Corning team has been developing technology for creating high-throughput ligand-binding assays for membrane proteins. By pin-printing nanogram quantities of commercially available membrane protein preparations onto the bottom of specially coated glass microwell plates—21 spots, for example, with three replicates of seven different proteins—they essentially create microarrays in the bottom of each well. The multiplex assays can then be performed using standard high-throughput screening automation.

Dr. Lai described a ligand-displacement assay in which the control will be an array incubated with a cocktail of labeled ligands known to be able to bind to those receptors, and all the spots will be lit up by fluorescent signals. When an unlabeled ligand is added to the mix, if it is able to bind the GPCR it will compete with the labeled ligands for binding, and thus the fluorescent signal at that spot will disappear in a dose-dependent fashion. “In a microplate you can screen many, many compounds in this way,” she said. It enables a large amount of information to be garnered using minimal reagents while saving valuable time.

Corning’s intention, Dr. Lai asserted, is more to provide a technology—in the surface chemistry suitable for immobilizing membrane proteins, and in the array-printing process that allows those proteins to remain functional—than to create assays themselves. It is actively seeking partners interested in marketing assays or providing services based on the technology.

Antibodies for All

Rather than printing spots on planar arrays or in microwells, Jochen Schwenk, Ph.D.’s group at the Science for Life Laboratory in Stockholm attaches antibodies to Luminex beads and queries the resulting suspension arrays with bodily fluids such as serum, plasma, urine, and cerebrospinal fluid.

Luminex offers up to 500 uniquely identifiable “colors” of bead, each of which can be conjugated with a different antibody. “The number that we usually communicate is that we run 384 samples, and each of those samples we run with 384 antibodies, on a daily basis,” yielding about 150,000 immunoassays per day, Dr. Schwenk said.

His work is an extension of that of the Human Protein Atlas, he explained, the stated goal of which is to explore the entirety of the human proteome using antibody-based proteomics. To date the HPA has produced antibodies against about 50%—roughly 10,000—of all nonredundant human proteins.

With this many proteins and this many antibodies to deal with, “we cannot invest time into optimizing each protocol—addressing each of these targets with antibodies that we need to maturate or support—so we’ve chosen to adjust the sample to suit the antibody best,” he said.

By heating biotin-labeled samples before mixing them with the antibody-coated beads, the epitopes of the proteins are often more exposed, and the functionality of the antibodies seems to be improved. Dr. Schwenk pointed out that “the advantage of using heat is that it’s something you can switch on or off, whereas if you add any chemical compound that would assist the denaturation, then you would need to remove that specific compound.” The group chose 56°C as “the balance between not too much and not too little—the problem is that for some targets if you heat the sample too much then you get precipitation and you lose some of the target.”

What makes SciLifeLab unique is that in addition to performing directed discovery it “also performs undirected discovery approaches, where we only use antibodies based on quality criteria and not necessarily on which proteins they target,” Dr. Schwenk said. “We have the possibility to identify new protein/disease associations.” It recently conducted a pilot study in which 4,500 antibodies were used to screen 600 samples covering 24 different diseases including 12 cancers, cardiovascular, and neurodegenerative diseases, and it is currently crunching the data.

The concept of next-generation plasma profiling, something that the Science for Life Laboratory is very interested in, is built on large and growing collections of affinity reagents that are implemented onto multiparallel platforms in order to analyze samples stored in biobanks in a hypothesis-free manner.