September 15, 2012 (Vol. 32, No. 16)

Firm Has Been Snapping Up Companies to Expand and Enhance Its Life Science Offerings

The recent acquisitions and collaborations made by Corning Life Sciences, combined with new technologies created in house, demonstrate that the company is committed to “growing our global business to serve drug discovery and biotechnology customers,” says Richard Eglen, Ph.D., vp and general manager of this division of Corning. Corning has manufactured consumables for life science laboratories since the introduction of Pyrex® flasks in 1915.

In June, Corning Life Sciences introduced the Corning® Synthemax® II-SC substrate at the International Society for Stem Cell Research in Yokohama, Japan. This self-coating synthetic surface reportedly mimics the natural cell environment. It supports adhesion and expansion of stem cells in their undifferentiated state and directs differentiation into specialized cell types.

Synthemax II-SC is a xeno-free alternative to biological coatings and mouse feeder cell layers used to grow human embryonic stem and induced pluripotent stem cell cultures. Materials scientists at Corning created this flexible surface that can be coated onto any vessel.

“Our combined expertise in surface chemistry, injection molding, and plastics puts us in a position to develop surfaces to optimize growth of specific cell lines. Synthemax is just one example of how this expertise has allowed us to continually develop specialized surfaces to meet emerging needs,” says Dr. Eglen.

Tapping TAP

Also in June, Corning Life Sciences entered into collaboration with TAP Biosystems to develop an automated system that handles up to four of Corning’s Hyperstack®-120 cell culture vessels simultaneously. This provides better control and more consistent results for high-throughput bioprocessing at a lower cost, Dr. Elgen notes.

Corning’s Hyperstack cell culture vessels “use our injection molding fabrication system to create a space to grow cells in high density within a small footprint,” he explains.

Compared to other stacked-plate products, the multilayered, gas-permeable film technology delivers more cells per volume, he continues, adding that cells grow with less variability on the expanded surface area, saving labor and space costs.

Hyperstack cell culture vessels, which are also available as closed systems, can be used for cell-line development, seeding, and manufacturing in bioprocessing systems.

All types of cells need nutrients to grow, and Corning Life Sciences expanded its product offering to include the cellgro® brand of cell culture media and molecular biology reagents for tissue and cell culture applications when it acquired Mediatech at the end of last year.

“Corning has a strong footprint in cell culture vessels, so acquiring Mediatech was a natural step forward,” says Dr. Eglen. The acquisition expands product offerings in off-the-shelf or fully customized beginning-to-end cell culture workflow solutions for upstream and downstream cell culture.

The product line, now sold as Corning cellgro, improves efficiencies and produces more reliable, consistent results, according to Dr. Eglen. Corning cellgro products include culture media, basal salt solutions, antibiotics, reagents, sera, and flexible packaging systems.

Combined with Corning’s disposable vessels and specialized surfaces, the cell culture media products form a comprehensive portfolio for cell culture growth, scale-up, sample preparation, separation, and harvesting, maintains Dr. Eglen.

“The combination of Corning’s Hyperstack vessels, closed system solutions, cellgro, and related single-use products play an important role in bioprocessing and scale-up operations,” he notes.

The acquisition of France-based Plastiques Gosselin added a range of consumables for microbiology and quality control testing. Gosselin’s products include Petri dishes, inoculating loops, dippers, containers, and disposable bags. These diversified consumables serve multiple industry segments, such as food, beverage, and environmental testing laboratories.

Currently undergoing regulatory approval is the agreement to acquire the Discovery Labware unit from Becton Dickinson. When complete, the acquisition will expand offerings in drug discovery tools, bioprocess solutions, and laboratory research instruments.

Corning Life Sciences will obtain four main product platforms from Discovery Labware—plastic consumables, including tubes, pipettes, Petri dishes, tissue culture dishes, and flasks; cell-based assays and cell cultureware; liquid-handling products; and ADME research.

“We expect the deal to close by the end of the year,” says Dr. Eglen.

With a keen interest in emerging countries, Corning Life Sciences recently opened a manufacturing and distribution center in Wujiang, China.

“We see China as an important part of our growth strategy,” points out Dr. Eglen, and the Wujiang facility “helps us capitalize on the growth of biotechnology and drug discovery there.”

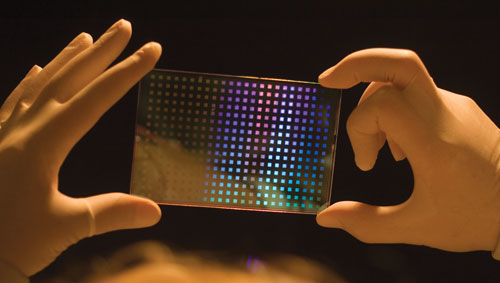

Corning Epic microplates for label-free detection

Epic Demonstrations

West coast clients have easier access to Corning technology and expertise at a recently opened demonstration laboratory located in the Corning West Technology Center in Palo Alto, CA. The lab allows clients to evaluate a range of Corning products, as well as collaborate directly with Corning scientists. Among other technologies, the lab houses a demonstration unit of the latest Corning Epic® label-free system.

This high-throughput screening platform is based on optical biosensor technology. It processes up to 40,000 wells in eight hours and integrates with existing automation.

The Epic System performs biochemical and cell-based drug discovery applications in 96-well, 384-well, and 1,536-well microplates and evaluates promising new drug leads. It also allows the observation of direct biological interactions that are not generally detected in high-throughput applications, explains Dr. Eglen.

Types of Epic assays include small-molecule binding, functional protease, kinase, protein-protein interactions, G-protein coupled receptors, viral detection, and ion channels. Corning field application scientists can provide hands-on training on the Epic System at the new demonstration lab. As Corning Life Sciences continues to grow, “we view drug discovery and biotechnology customers as strong components of our customer base,” says Dr. Eglen. Other laboratories that offer Epic System demonstrations are located in Kennebunk, ME, and Fontainebleau, France.

Researchers can visit another applications laboratory at California-based Axygen, which Corning Life Sciences acquired in 2009. Axygen’s product portfolio includes tips for manual and robotic applications, PCR consumables, and a range of magnetic bead-based kits and accessories to increase efficiencies in nextgen sequencing and genomics workflows.

Corning customers have access to the company’s technology and expertise at demonstration labs scattered throughout the world. Axygen Laboratory Training is located in Union City, CA.