By Andreas Frerix, PhD

Today’s most common biopharmaceutical manufacturing systems require the handling, transferring, processing, and purification of large-molecule drugs produced in living cells—cultured animal cells, bacterial cells, or yeast cells. These operations, which are performed with the materials in a liquid phase, require the use of pump technologies that can reliably provide volumetric consistency and accuracy, appropriate pressures and flow rates, and low pulsation (to sustain processing conditions), as well as low-shear, low-heat input and material compatibility (to protect the biological drug from being harmed).

Traditionally, permanent stainless-steel pumping and processing systems have been used for upstream and downstream operations, but the time and costs involved in the operation, cleaning, maintenance, and quality control of a system to prepare for the next production run can become prohibitive. Such concerns led to the creation of single-use pumps that feature a disposable pump head and chamber that can be easily removed and replaced between production runs, eliminating the time and costs needed to revalidate the equipment in a stainless-steel system.

This technology, though, still required improvements to optimize changeover times and simplify installation processes. An important advance in this area came with the development of a pump chamber changing system that reduces the time needed to replace a disposable single-use pump chamber to seconds.

Before proceeding, we should take a step back and discuss what the terms “complex,” “precise,” and “pure” mean in the context of biopharmaceutical manufacturing. The foundation of biopharmaceutical manufacturing rests on various types of unit operations. Whereas each unit operation features its own set of operational criteria, all unit operations are alike in that they can produce a viable, contaminant-free drug suitable for human administration only if the manufacturer strictly adheres to an unbending set of operational parameters and structures.

Three of the more common unit operations in biopharmaceutical manufacturing are tangential flow filtration (TFF), chromatography, and virus filtration. TFF is also known as cross-flow filtration, a process in which the biopharmaceutical’s feed stream flows tangentially across the filter membrane at positive pressure. Whereas TFF is used to concentrate the product based on the molecule size, chromatography is a process that is used to purify target molecules from the other process stream based on adsorption to a resin. Virus filtration is used to ensure the safety of the drugs that are produced.

The common thread among these various types of unit operations is that each needs a pumping technology that can satisfy its specific operational parameters.

Single-use solution

Some additional mention must also be given to the advantages that utilizing single-use quaternary diaphragm pumps in biopharmaceutical manufacturing can deliver. The main advantage for these pumps, whether used in traditional stainless-steel or single-use setups, is their unique form of operation.

The four quaternary diaphragms are driven one after another by a connector plate, which moves back and forth out of its central position in a stroke that is generated by an eccentric shaft, with the length of the stroke determined by the angle of the eccentricity. The four pumping chambers, which actually operate in the same way the human heart does, keep the product flow constantly moving forward in a volumetrically consistent low-shear and low-pulse manner.

The pump’s chambers also contain no rotating parts that can be subject to friction, meaning that there is minimum heat buildup that can compromise the product. This mode of operation means that the pumps can run dry, are self-priming, and produce minimal shear because of low slip. In addition, they offer low-pulsation, leak-free operation while having great dry/wet suction-lift capabilities.

The quaternary diaphragm pump is also adaptable to single-use production configurations. A single-use pump enables biopharmaceutical manufacturers to essentially eliminate the oftentimes prohibitive costs of cleaning and validating pumps and systems. The result is a quicker and more cost-effective production process, and one that still delivers preferred levels of product purity and sterility with no chance for cross-batch or cross-product contamination.

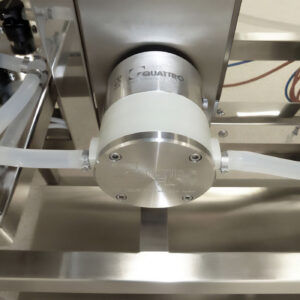

The fulcrum of the single-use pump is its product-wetted plastic pump chamber. This

chamber can be replaced as a complete unit.

Next step forward

Chamber Replacing

System from Quattroflow

allows single-use quaternary

diaphragm pump chambers to be

replaced in as little as 30 seconds

without the need for special tools or

torque wrenches. The result is decreased downtime during product changeovers and an improved production process.

Although single-use pump technology succeeded in reducing the time and costs associated with cleaning and revalidation after production runs, there was still interest in further reducing the time needed for pump head replacement. The breakthrough came with the development and release of a pump chamber replacement system, specifically, the Quattroflow EZ-Set.

The system reduces downtime in the production changeover process. It allows manufacturers to replace a single-use pump chamber in 30 seconds or less without the need of torque wrenches or other special tools and equipment—all while allowing the user to wear rubber gloves during the replacement process.

Pump chamber replacing systems can also be retrofitted on existing motor drives, which also makes upgrades quick and easy to perform.

The five steps that are needed to replace the pump chamber

are as follows:

• Remove the pump’s pressure plate.

• Take the pump chamber out of the ring drive.

• Push the new pump chamber onto the ring drive.

• Reinstall the pressure plate.

• Slightly rotate the pressure plate to lock.

Conclusion

Many skills are needed to produce biopharmaceuticals, but in the end, the final product must be one that is unquestionably safe to use while simultaneously allowing the manufacturer to reap the financial benefits of an optimized patent window. The arrival of single-use pumps on the scene has virtually eliminated the cost and downtime that were previously required to clean and validate pumping systems.

Andreas Frerix, PhD ([email protected]), is the product management director for Quattroflow at PSG, a Dover company. Website: www.psgdover.com.