June 15, 2011 (Vol. 31, No. 12)

Wendy Gaisford

Brian Everatt

LAB2LAB Designed to Connect Remote Labs to a Central Instrument Facililty

The drive to increase the speed and efficiency of the development of novel chemical entities for drug candidates has resulted in huge investments in analytical instrumentation by major pharmaceutical companies.

Analytical instrumentation is used at all stages of the synthesis of chemical compounds—to characterize and ensure the integrity of chemical intermediates during a series of reaction steps, to analyze chemical composition after final purification, and for quality control of the compound during storage and before biological assay. From the chemist’s perspective, the ability to quickly perform high-quality analysis during all stages of the chemical reaction is vital in the development of new chemical compounds.

The introduction of new high-spec instrumentation into a research establishment often brings with it increased financial and infrastructure burdens due to their size and high maintenance costs. As a result it is not feasible to be able to have equipment in every laboratory.

Rationalization of research equipment is often necessary and in many research establishments analytical equipment is housed in a central laboratory. This poses problems to the research chemist as often, throughout the day, there will be a need to analyze chemical intermediates while performing a series of reactions.

Although analysis of these intermediates using high-quality LC/MS instruments is often more informative, the time taken to walk to the central analytical lab and run the sample may make it impractical to monitor chemical synthesis in this way. For speed, cruder lab-based techniques such as HPLC and thin-layer chromatography are often carried out, which cost less to perform but provide less information.

Even at the final synthesis stage, submission of chemical compounds to equipment such as HPLC and GC/MS requires substantial manual effort. Typically samples are formulated, collated into racks, and transported to a central analytical laboratory. The scientist then has to manually enter these samples into analytical instrumentation, which can be a time-consuming, error-prone, and inefficient process.

More likely than not, transportation of samples for analysis requires the scientist to travel long distances, between floors or even buildings. The possibility of queues when the scientist arrives at the analytical lab can be a frustrating experience, taking the scientist away from his research objectives and work.

TTP LabTech has developed an automated laboratory transport and management system for connecting remote laboratories to a central instrument facility. Run by software compatible with the scientist’s electronic notebook (ELN), LAB2LAB transfers samples from remote laboratories and connects to existing analytical instrumentation such as HPLC, LC/MS, GC/MS, UPLC, and NMR.

According to the scientist’s instructions, the sample for analysis is either automatically sent to their chosen analytical instrument, or if the sample is low priority it is placed in a holding buffer allowing automated analysis at a time when the equipment is in less demand. LAB2LAB allows unattended operation of equipment, thereby reducing sample queues, optimizing instrument use, and increasing the speed of data generation.

The system connects labs from anywhere in the building to analytical instrumentation via a low-pressure compressed-air system. Each sample tube has a distinguishing 2-D barcode. To submit a sample, the chemist scans the tube and selects one or more methods. An ELN reference is assigned, and the tube is placed in a LAB2LAB benchtop sender.

LAB2LAB transports and directs samples via a router to the most appropriate analytical instrumentation available. Samples are either placed in a holding buffer or sent directly for analysis and the results are automatically returned to the originator’s ELN. Following analysis, and according to the scientist’s instructions, the sample may be returned, sent to another instrument for further analysis, or placed in a waste bin for later removal.

Case Study

Recent installation of LAB2LAB at the Novartis Institutes for BioMedical Research has enabled scientists to assess the benefit of remote connection of six chemical laboratories over three floors to a central analytical lab.

In the first phase of installation, the linking of six medicinal chemistry labs to an Agilent 1100 HPLC for analysis in a central lab was demonstrated. Following this, one and then later on, two Waters Acquity UPLC-MS instruments for reaction monitoring were installed on LAB2LAB, and a significant increase in productivity was observed.

Results of a study assessing the time necessary for a chemist to physically submit a sample vial to UPLC-MS instrumentation and to receive data into their ELN on a single day is shown in Figure 1. On this day 180 samples were submitted to two Acquities, and the average time taken for the results to be returned was 11 minutes, 34 seconds. Data included samples that had been submitted for multiple methods, including samples that were submitted using methods that would take longer than the standard two-minute reaction-monitoring analysis.

Figure 1. Average time following sample submission for data to be returned to the ELN

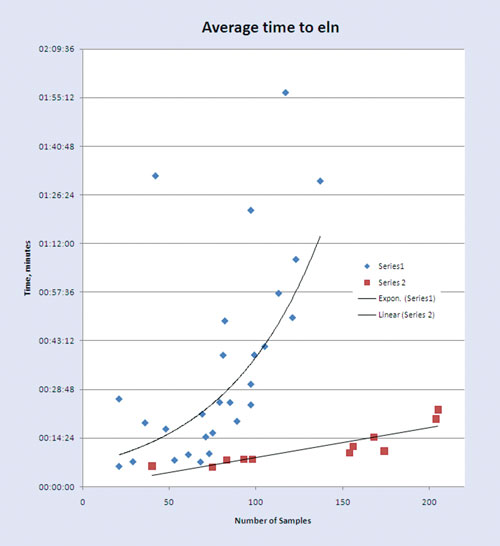

In a further study, the average time taken to obtain results was plotted against the number of samples run on each day (Figure 2). Each point on this graph represents a single day, and shows the samples submitted by more than 50 chemists working in the six medicinal chemistry labs.

Figure 2 shows the response of a single UPLC-MS (Series 1) and two UPLC-MS instruments (Series 2). It was observed that as the number of samples per day increased to more than 100, a single UPLC-MS instrument struggled to cope. However, the addition of a second analyzer within LAB2LAB, enabled the management of queuing and sample distribution, reducing the queue time significantly. In this study more than 250 samples per day were being run with an average queue time of less than 30 minutes.

Additionally, outliers show the effect on queue times as a result of taking an instrument offline for maintenance.

These analyzers were able to support in excess of 250 sample submissions per day with an acceptable time to return data to the ELN. As the flow of samples is dependent on several factors including the difficulty of the chemistry, the number of chemists working on a project, and the time of day, it is difficult to optimize the performance and achieve full capacity. However, addition of more instruments running the same methods will enable greater numbers of samples to be analyzed rapidly. Addition of different instruments will enable LAB2LAB to provide the chemist with a virtual instrument in every laboratory, capable of running a variety of methods on each sample. It is possible to load larger samples directly into the buffer therefore enabling automatic analysis of a compound library.

Figure 2. Addition of a second UPLC-MS instrument reduces queue time

Wendy Gaisford ([email protected]) is science writer at TTP LabTech. Brian Everatt is an investigator III at Novartis.