February 1, 2016 (Vol. 36, No. 3)

Eric S. S. Langer President and Managing Partner BioPlan Associates

Industry Looks for Viable Alternatives but Doesn’t Jump to Implement Them

Protein A resins continue to dominate purification of monoclonal antibodies (mAbs), as they are a proven technology and form the basis for many downstream purification platforms that have long satisfied regulators. Yet Protein A remains a major cost and bottleneck in bioprocessing; as such, the search for viable alternatives continues.

Today, most major biologics are manufactured using Protein A resins. Some exceptions like Abbvie’s Humira use hydrophobic interaction chromatography for initial antibody capture-based purification. But while the industry shows a strong interest in Protein A alternatives, inherent conservatism in adopting new technologies—coupled with a lack of cost-effective alternatives—has held most back from making the switch.

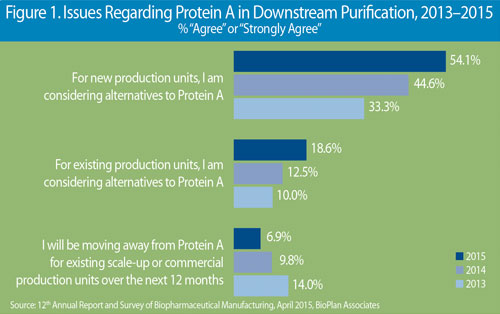

Our industry data demonstrates this reluctance and/or inability to switch persists and even grows more pronounced in spite of sustained interest. In our most recent industry Annual Study, we found increasing interest in switching over the past couple of years, but a decreasing commitment to actually doing so.

In other words, while more respondents are considering alternatives to Protein A for existing production units, the percentage who said they would be moving away has declined.

It’s possible that, given market dynamics, as more companies switch to alternatives, fewer plan to do so. In fact, we separately found a relatively small, yet noteworthy increase in the proportion of industry respondents who reported having already switched to alternatives in order to improve their downstream purification operations. In 2015, 8.6% of respondents reported actually having made such a move, up from 4.8% a couple of years prior, in 2013.

Who’s Switching?

It’s interesting to see who’s making the switch to Protein A alternatives. Although contract manufacturing organizations (CMOs) are typically the ones leading the charge in the adoption of new technologies, in this case, our data indicates that biotherapeutic developers are just as likely to have made the switch to alternatives.

Meanwhile, while Western European companies show some interest in switching, few report having done so in our most recent study, with this appearing to be a more pressing issue in the United States.

Emerging Alternatives

Part of the problem is the lack of viable cost-effective, regulatory-acceptable alternatives to the tried-and-true (but expensive) current paradigm. Our study takes an in-depth look at the Protein A market, identifying just a few of the alternatives:

• Protein L-based resins such as Capto L resins;

• MPTselect Protein A Affinity Resin;

• ProVance Protein A pre-packed columns;

• Conventional resins such as Thiophilic adsorption, hydrophobic charge induction chromatography and peptide-based mimetics; and

• Affinity proteins such as bacterial proteins, camelid antibodies and FcgRI as ligand.

While Figures 1 & 2 show that the Protein A market is ripe for disruption, none of these alternatives has yet to capture any meaningful market share. There have been advances in the packaging and marketing of Protein A resins in the form of prepacked single-use columns, however. These have gained more interest over the years, with more than one-third (37%) reporting considering single use pre-packed columns, up from 22% a couple of years ago.

There’s reason to believe that more companies will switch to Protein A alternatives in the future; even though fewer suppliers are working on Protein A alternatives relative to earlier this decade, these alternatives remain in the top third of new technologies that suppliers are working on. And with the high cost of Protein A and operational capacity bottlenecks related to chromatography, end-user demand for alternatives will likely increase in the near future.

Eric Langer ([email protected]) is managing partner at BioPlan Associates.